NO MORE BROWNOUTS ! CONTACT US NOW ! Email : purepower@herculespower.com

Engine Noise Level Guide

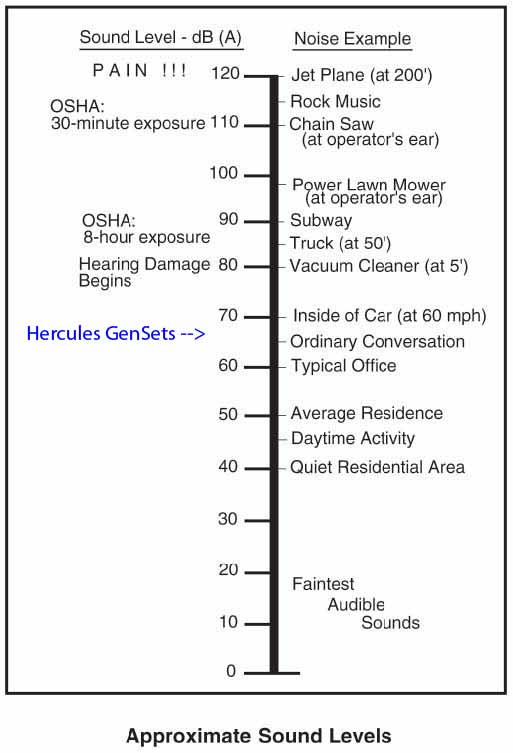

SOUND AND NOISE Sound consists of pressure waves traveling through the air (or water, etc.). Sound pressure waves can be described by their frequency and amplitude. Noise is unwanted sound, usually consisting of many pressure waves at different frequencies and amplitudes. FREQUENCY “Frequency” refers to the number of pressure waves per second. It is usually reported as “Hertz” (Hz), which means cycles per second. The human ear can usually detect frequencies from about 20 Hz to 20,000 Hz. AMPLITUDE (DB AND DB(A)) “Amplitude” refers to the pressure level of the sound wave. Since sound pressure variations are extremely small and cover a very wide range, they are usually measured on a logarithmic scale called Decibels (dB), instead of conventional pressure units like psi. Since the human ear has different sensitivities at different frequencies, a 50 dB sound at 200 Hz would not sound as loud as a 50 dB sound at 2000Hz. For that reason noise measurements are usually reported in dB(A). The “A” refers to a set of weighting factors based on the sensitivity of the human ear at each frequency. There are other weighting systems such as dB(B) and dB(C), but most machinery and vehicle sound regulations are in dB(A). Zero dB(A) approximately equals the lowest possible pressure wave audible to the human ear at each frequency. Each increase in amplitude of 6 dB represents a doubling of sound pressure level. Using the “A” weighting system, a 50 dB(A) sound at 200 Hz should sound approximately as loud as a 50 dB(A) sound at 2000 Hz. Sound levels from typical sources are shown in Figure 50-1. ADDING SOUND LEVELS Since the Decibel scale is logarithmic, Decibels can’t be added directly. When adding sound levels the loudest sound dominates. Adding additional sound sources that are not as loud have relatively little effect. The following chart can be used to add decibel levels from different sources or at different frequencies. Use the chart to add two decibel levels at a time. If you have to add three or more sources, add any two, then add that total to the third, etc. To use Figure 50-2, first determine the difference between the two values being added. Subtract one value from the other to find the difference, locate the difference on the horizontal (bottom) axis of the chart, draw a straight line up to the curve, then over to the vertical (side) axis of the chart to fi nd out how many decibels to add to the higher of the two original values. For example, if you were adding an 84 dB(A) source to a 90 dB(A) source, the difference would be 90-84=6. From the chart you can see that for a difference of 6 decibels you should add 1 decibel to the highest of the two levels, so you would add 1 dB(A) to 90 dB(A) for a combined level of 91 dB(A) for both sources. If you are adding two equally loud sources, say 90 dB(A) each, the difference would be zero, and you would add 3 dB(A) to 90, for a combined level of 93 dB(A) for both sources. DISTANCE EFFECTS Decibel level drops off rapidly with distance. Exactly how much depends on how much the ground and other close objects reflect or absorb sound. In a free field (no absorption or reflection), sound will drop off by 6 decibels for each doubling of distance from the source. You can use this to estimate the effect of increasing or decreasing the distance to the noise source. For example, a noise source of 90 dB(A) at 7 meters would be about 84 dB(A) at 14 meters, or 96 dB(A) at 3.5 meters. “ENGINE NOISE” SOURCES Several different noise sources contribute to what people sometimes consider “engine noise.” The noise levels reported on the back of each engine performance curve are only the noise radiated directly off the bare engine surfaces. They are averages of several microphones located 1 meter from the engine. They do not include noise from the exhaust system, fan, etc. Engine surface noise may not be the largest noise source. Exhaust noise is frequently higher, and fan noise can be, in some installations. Other signifi cant noise sources can include the air intake, drive train, hydraulics, tires, etc. NOISE TREATMENT - GENERAL Noise can be transmitted from any noise-generating component in the form of “air-borne” noise or “structure-borne” noise. Air-borne noise is transmitted directly from the surfaces of the component through the air to the ear. Structure-borne noise is transmitted through the engine mounts or other solid connections to the cab or chassis in the form of vibration, then from there it goes through the air to the ear. Most noise treatments work on either structure-borne or air-borne noise in one of the following ways: SOURCE REDUCTION Generating less noise at the source, by specifying quieter engines, transmissions, tires, etc. SHIELDING - A heavy wall that will not vibrate easily, placed between the noise source and the ear, can help block the pressure waves. This is what concrete “noise fences” along highways do. Heavy, solid, well-damped materials (such as concrete, lead, or heavy rubber) make the best shields. Lighter shield materials (such as sheet steel) are most effective when used in combination with absorptive material and/or damping. ABSORPTION - Plastic foam, fabric, or other soft porous materials can quiet sound by absorbing some of the sound pressure waves. Both absorption and shielding are most effective on high-frequency vibrations. That’s why when a car with a loud stereo passes your house, you hear only the bass. ISOLATION - Rubber mounts can be used to keep structure-borne noise from being transmitted from the engine or other noise sources to cabs or sheet metal that could transmit the noise to the ear. Any solid connection can transmit structure-borne noise, including throttle levers, exhaust system brackets, etc. Isolating noise sources (such as engines and muffl ers) can be effective. But if the operator is enclosed in a cab, isolating the cab can provide the best results. STIFFENING - When structure-borne or air-borne noise is transmitted to cabs, chassis or shields, resonant vibrations can be excited in sheet metal panels, amplifying the noise. Stiffening panels by adding stamped-in or added-on bases can help detune resonant frequencies and reduce amplitudes. DAMPING - Sometimes resonant vibrations in sheet metal panels can be absorbed by adding layers of damping materials (such as rubber or tar-like substances) to the panels. This is why automotive undercoating makes cars quieter. SEPARATION - Dominant noise sources should be physically separated so they do not add together. For example, if the engine surfaces and the exhaust pipe produce 90 dB(A) each, they will produce 93 dB(A) together. But if the exhaust pipe is routed to the opposite end of a large machine, the noise at either end will be close to 90 dB(A). NOISE TREATMENT - SPECIFIC NOISE SOURCE IDENTIFICATION The most important rule in noise treatment is to identify the noisiest component, and concentrate your control efforts on it. Even if you completely eliminate the second or third noisiest source it can’t have more than a few dB(A) effect. If the noise goes down 3 dB(A) or more when one source is eliminated, it is larger than all other sources combined. A reduction of 1 or 2 dB(A) may also be significant if there are many sources close in amplitude. You can identify the primary noise source by temporarily removing or treating each source one at a time. Fan noise is easy to check by removing the fan temporarily. To isolate transmission or drive train noise, disconnect the clutch. To isolate exhaust or intake noise, reroute them away from the machine to check their contribution. EXHAUST NOISE Exhaust noise is the loudest untreated noise source on most applications and is also the easiest to treat. Standard mufflers can reduce exhaust pipe noise by 10-15 dB(A) through absorption. Quieter “residential” mufflers are also available. The best source of muffler performance information is your muffler supplier. The exhaust pipe should direct exhaust flow away from the cab, the operator, and bystanders’ ear level. For ultra-quiet installations it may be necessary to wrap the muffler with high-temperature (ceramic) fabric and a sheet metal cover, to shield and absorb air-borne “skin-noise” from the muffler shell. The muffler can also transmit structural noise to the cab or frame. Avoid bracketing the muffler or exhaust pipes to the cab or frame if possible. If it’s necessary to support the muffler on the cab or frame, isolate the exhaust system using flexible exhaust connectors to break the structural vibration path, or use rubberized exhaust pipe hangers such as used on passenger cars. FAN NOISE Fan noise, due to a large-diameter fan turning at high rpm, can be greater than noise coming from the exhaust pipe or engine compartment. Fan noise can be controlled by following these guidelines: • Run the fan as slow as possible. Fan tip speeds (fan rpm x circumference) of 12,000 feet per minute or less are recommended for quiet installations. If the fan is running over 16,000 fpm, it may be the loudest noise source on the machine. • Follow the fan application guidelines in the Cooling Section of this manual to maximize fan efficiency. For the same air flow, an efficient fan can be run slower than an inefficient fan. Large fans at slow rpm are usually quieter than small fans at high rpm for the same air flow. • Air obstructions cause noise when a fan blade moves past them, particularly on the inlet side. Keep the fan at least 1/2 to 1 blade width back from the radiator and well away from engine obstructions (such as alternator pulleys, hoses, etc.). • Use shielding and absorption to reduce fan noise at the source. ENGINE AIR-BORNE NOISE Hercules engines are among the quietest in the industry. Generally speaking, engines run somewhat quieter at lower speeds, but other than reducing speed, there is very little you can do to reduce engine surface noise at the source. The most effective way to treat engine surface noise is by using an enclosure lined with absorptive materials. Sound enclosures work best when as much of the machine as possible is contained within the enclosure. Ideally, the entire machine should be enclosed. This has the added advantage of helping to silence any other noise sources (such as the fan, transmission, etc.) that are also located in the enclosure. To provide effective shielding, the enclosure should be sealed as completely as possible, except for air flow openings. Openings for air flow should be generous, but they should be baffled to direct air flow over sound absorbing materials and away from ear level. The use of a blower fan should be strongly considered to control engine compartment temperatures. Wrapping and shielding of exhaust components will also help. Exhaust should be routed out of the compartment along with the cooling air flow so it does not recirculate in the engine compartment. With blower fans (as shown) it should exit in the front. With suction fans, exhaust should exit in the rear. With blower fans, the air cleaner inlet can be taken from within the engine compartment. With suction fans, it should be taken from in front of the radiator, but within the front sound shield. Care must be taken to make sure the sound absorbent materials used can tolerate the high temperatures that can be present in the engine compartment. How high the temperature will be depends on your installation. Exhaust gases or hot components must be kept away from any flammable sound absorbent material. Sound absorbent material should be used cautiously below the engine, particularly if any oil leaks are present. Oilsoaked absorptive material can be combustible. ENGINE STRUCTURE-BORNE NOISE Engines can also transmit structure-borne noise from vibration to frames and cabs. Hercules fully balanced 4-cylinder engines produce significantly less vibration than competitive 4-cylinder engines. Well-matched rubber engine mounts can also help reduce structural noise transmission. However, poorly matched rubber mounts can be worse than solid mounts. Refer to the Engine Mounting section of this manual for mount design guidelines. Remember that other solid connections such as rigid exhaust pipes will prevent rubber mounts from working properly, and will transmit structure-borne noise themselves. AIR INTAKE NOISE Air intake noise is usually adequately muffled by using a properly sized canister type air cleaner. If you are using a small or “throw-away” type air cleaner and air intake noise is a dominant noise source, consider changing to a canister. Call us now at : Tel : 63-2-7359810, 63-2-4002650 Mobile : 63-090-88881668 Email : purepower@hercules-power.com

|

Electricity Anytime Anywhere !!! Email : purepower@herculespower.com

Telephones: 87359810, 84002650, 87169141

0908-888-1668( Smart ) , 0917-830-0578(Globe)